Fixed Speed Screw Air Compressor

Product Description

Controller

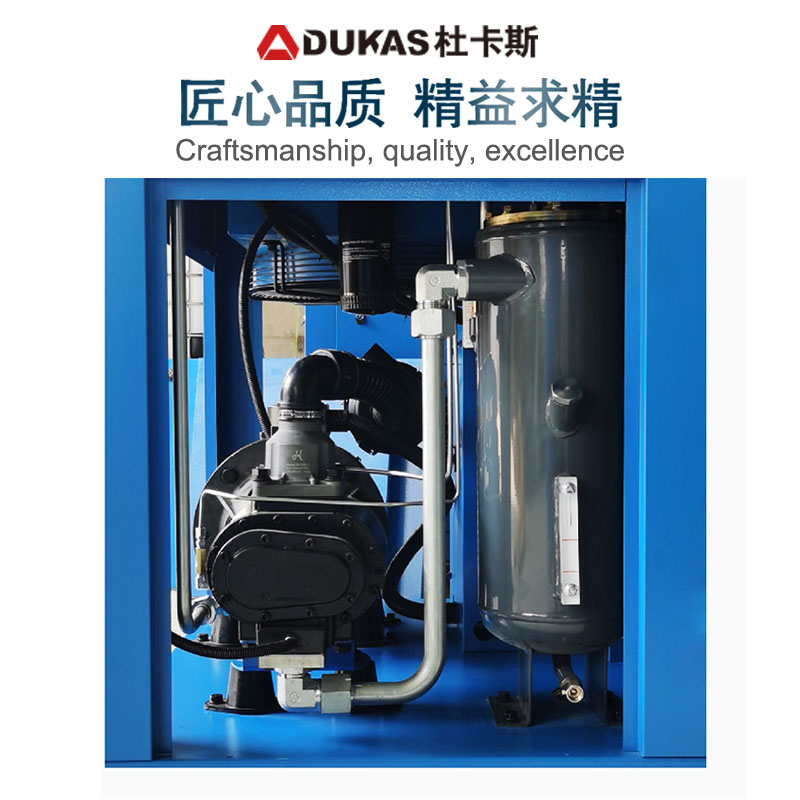

Adopts the international top-level third-generation asymmetric wire twin-screw air end, adheres to the exquisite manufacturing process, adopts the peak high efficiency low-pressure, high-efficiency tooth shape and the axial air inlet design.

Inverter

The standard is equipped with high frequency reactor, effectively reducing the frequency converter and the external magnetic field dry reactance.

Cooler

The heat exchanger uses high-quality raw materials and a unique internal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

Oil filter

Adopts high-density filter material, the surface is treated with nano-electroplating.

Oil separator

The high-quality air-oil separation element and gas-liquid filter element are equipped with advanced three-stage air-oil separation to keep the oil content below 3ppm to ensure the output of high-quality compressed air.

Air end

Adopts the international top-level third-generation asymmetric wire twin-screw air end, adheres to the exquisite manufacturing process, adopts the peak high efficiency low-pressure, high-efficiency tooth shape and the axial air inlet design.

Fan

The fan uses a large fan design to effectively enhance the fan's heat dissipation effect.The motor adopts a special internal design to adapt to harsh working conditions.

Motor

The motor uses high-performance motors of well-known brands. Permanent magnet synchronous motors (PM motors) use high-performance NdFeB permanent magnets which will not lose magnetism under 200 ° and its service life reaches as long as 15 years.

Intake valve

Adopting the world famous brand air intake valve, it can automatically adjust theair volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action and long life consequently reduced operating costs.

Air filter

Adopting a design with high dust holding capacity and low flow resistance, which can filter out tiny fixed particles in the air. The dust removal effect can reach 99.5%, ensuring the normal operation of the components of the system and extending the service life.

Team With Customers

In May 2015,Australian customer come to visit dukas,we provide them with a complete agency agreement.

In September 2016,Indian customer come to visit dukas,we sign an annual cooperation agreement.

In October 2016,Turkish customer come to visit dukas,we make the deal of first order and keep cooperation until now.

In June 2017,British customer come to visit dukas,Inspect the compressor they ordered and place a yearly order after the visit.

In November 2018,Israeli customer come to visit dukas,Inspect our factory and we make a training their engineer.

In July 2018,Bangladeshi customer come to visit dukas,he test our compressor performance and we make agreement after test successful.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Advantages of Dukas Screw Air Compressor

1. Intelligent Control System with big touch screen

Direct display of discharge temperature and pressure, operating frequency,current,power,operating state.Real time monitoring of discharge temperature and pressure, current, frequency fluctuations.

2. Wide Working Frequency Range To Save Energy

Frequency conversion ranges from 5% to 100%.When the user s gas fluctuation is large, the more obvious energy saving effect and the lower the low-frequency running noise, applicable to any place.

3. Small Start-up Impact Protect Factory Power System

Use frequency conversion permanent magnet motor, start smooth and soft.When the motor starts, the current does not exceed the rated current, which does not affect the power grid and the mechanical wear of the main engine, greatly reduces the power failure and prolongs the service life of the main screw machine

4. Humanized Canopy Design Easy To Maintain

The compressor features a solid construction hence is build to last. All the parts of the air compressor are made of quality material that will last for years.

Apart from refilling the lubricant, you only need to perform other basic air compressor maintenance practices.

5. The Latest Generation Super Stable Inverter Keep Optimal working mode

Constant pressure air supply, air supply pressure is accurately controlled within 0.01Mpa.Constant temperature air supply, general constant temperature set at 85℃, make the best oil lubrication effect and avoid high temperature to stop.No empty load,reduce energy consumption by 45%, eliminate excess pressure.For each 0.1mpa increase of air compressor pressure, energy consumption increases by 7%.Vector air supply ,accurate calculation, to ensure that the air compressor production and customer system air demand at all times to maintain the same.

6. Supply Clean Compressed Air

The equipment working with compressed air are generally focus on the air pressure, but many people ignore that in addition to the pressure of compressed air, its cleanliness affects the life of the equipment. Such as the use of electronic optics equipment, like laser cutting machines, color sorters and so on. we use a high performance oil separator and cooling system to ensure that provide the cleanest compressed air to your equipment.

7. Longer warranty compare to other companies

Our warranty is 2 years for complete machine, compare to other companies, mostly of them are providing 1 year warranty. With 20 years experience we have confidence to make good service to our customers all over the world.

Specifications

PM VSD Screw Air Compressor specification 7.5kw-45kw

| Model | DKS-7.5V | DKS-11V | DKS-15V | DKS-18.5V | DKS-22V | DKS-30V | DKS-37V | DKS-45V | |

| Motor | Power(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Horsepower(ps) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

| Air displacement/Working pressure(M3/Min./MPa) | 1.2/0.7 | 1.9/0.7 | 2.5/0.7 | 3.2/0.7 | 3.8/0.7 | 5.3/0.7 | 6.8/0.7 | 7.4/0.7 | |

| 1.1/0.8 | 1.7/0.8 | 23/0.8 | 3.0/0.8 | 3.6/0.8 | 5.0/0.8 | 6.2/0.8 | 7.0/0.8 | ||

| 0.9/1.0 | 1.6/1.0 | 2.1/1.0 | 2.7/1.0 | 3.2/1.0 | 4.5/1.0 | 5.6/1.0 | 6.2/1.0 | ||

| 0.8/1.2 | 1.4/1.2 | 1.9/1.2 | 2.4/1.2 | 2.7/1.2 | 4.0/1.2 | 5.0/1.2 | 5.6/1.2 | ||

| Air outlet diameter | DN20 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 18 | 30 | 30 | 30 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 64±2 | 66±2 | 66±2 | 66±2 | |

| Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| Start method | PM VSD | PM VSD | PM VSD | PM VSD | PM VSD | PM VSD | PM VSD | PM VSD | |

| Weight (kg) | 220 | 350 | 360 | 510 | 510 | 650 | 700 | 780 | |

| Extenal dimensions | Length (mm) | 900 | 1100 | 1100 | 1200 | 1200 | 1460 | 1460 | 1460 |

| width (mm) | 680 | 730 | 730 | 880 | 880 | 980 | 980 | 980 | |

| Height (mm) | 800 | 980 | 980 | 1080 | 1080 | 1230 | 1230 | 1230 | |

PM VSD Screw Air Compressor Specification 55kw-132kw

|

Model |

DKS-55V |

DKS-75V |

DKS-90V |

DKS-110V |

DKS-132V |

||

|

Motor |

Power(kw) |

55 |

75 |

90 |

110 |

132 |

|

|

Horsepower(ps) |

75 |

100 |

125 |

150 |

175 |

||

| Air displacement/ Working pressure (M3/Min/MPa) |

10.0/0.7 |

13.4/0.7 |

16.2/0.7 |

21.0/0.7 |

24.5/0.7 |

||

|

9.2/0.8 |

12.6/.0.8 |

15.0/0.8 |

19.8/0.8 |

23.2/0.8 |

|||

|

8.5/1.0 |

11.2/1.0 |

13.8/1.0 |

17.4/1.0 |

20.5/1.0 |

|||

|

7.6/1.2 |

10.0/1.2 |

12.3/1.2 |

14.8/1.2 |

17.4/1.2 |

|||

|

Air outlet diameter |

DN50 |

DN50 |

DN50 |

DN65 |

DN65 |

||

|

Lubricating oil volume (L) |

65 |

65 |

72 |

90 |

90 |

||

|

Noise level dB(A) |

68±2 |

68±2 |

70±2 |

70±2 |

70±2 |

||

|

Driven method |

Direct driven |

Direct driven |

Direct driven |

Direct driven |

Direct driven |

||

|

Start method |

PM VSD |

PM VSD |

PM VSD |

PM VSD |

PM VSD |

||

|

Weight (kg) |

1250 |

1350 |

1950 |

2200 |

2500 |

||

|

Extenal dimensions |

Length (mm) |

1750 |

1750 |

2450 |

2450 |

2450 |

|

|

width (mm) |

1280 |

1280 |

1660 |

1660 |

1660 |

||

|

Height (mm) |

1590 |

1590 |

1700 |

1700 |

1700 |

||

Products categories

-

E-mail

E-mail

-

Phone&

Whatsapp -

Top