Ten Standard Copywriting Points on the Applicable Scenarios and Features of Two-Stage Permanent Magnet Variable Frequency Air Compressors

Utilizing two-stage compression technology, it achieves optimal pressure distribution and efficient cooling between stages, saving up to 15% more energy than single-stage compression. It is an ideal choice for industrial users seeking ultimate energy efficiency and long-term cost control.

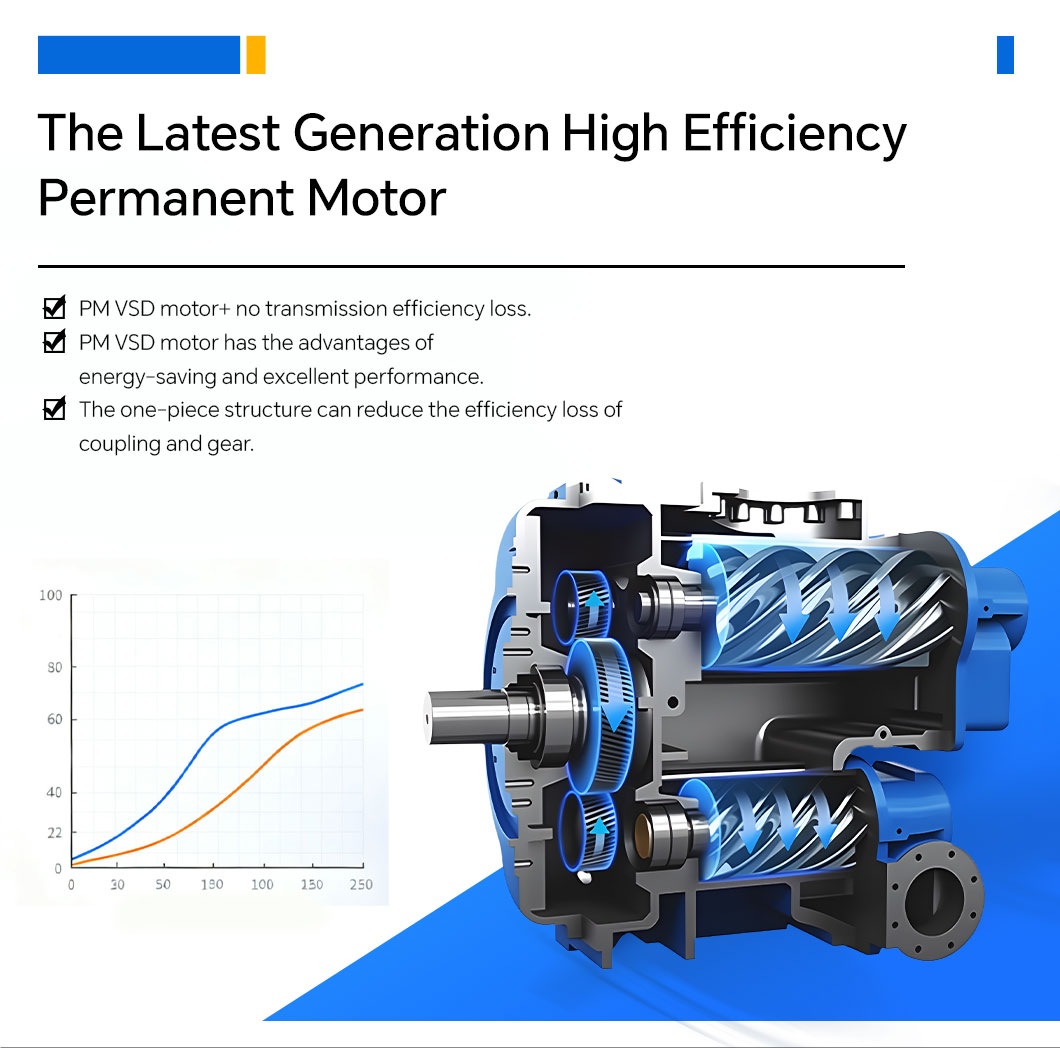

Equipped with a high-efficiency permanent magnet synchronous motor, it requires no excitation current, has high starting torque, and achieves an efficiency of up to IE5 ultra-high efficiency. It maintains ultra-high operating efficiency across all operating conditions, significantly reducing energy loss.

Combining permanent magnet variable frequency technology, it achieves stepless precision adjustment within a load range of 15-100%, with exhaust pressure fluctuations controlled within ±0.05 bar, meeting the stringent requirements of precision instruments and high-end manufacturing for extremely stable air pressure.

Designed for high-temperature environments, the two-stage compression significantly reduces the compression ratio and exhaust temperature of each stage. The unit can maintain efficient and stable operation even at 45℃, extending the life of lubricating oil and core components.

Post time: Jan-09-2026