DUKAS laser cutting air compressor: intelligent monitoring, energy saving, and stable operation.

Integrated design saves installation space and costs

Features/Advantages: Integrates the air compressor unit, refrigerated dryer, precision filter, and air tank into one unit. It is pre-commissioned and tested before leaving the factory; users only need to connect the power supply and air outlet pipe to use it, greatly saving installation space, time, and piping costs.

Easy maintenance and low lifecycle cost

Features/Advantages: The oil-free design eliminates the hassle and cost of changing oil and oil filters. Major maintenance only involves periodically replacing a few easily worn parts such as the air filter. Long maintenance intervals and strong planning capabilities effectively reduce the risk of unplanned downtime and long-term maintenance costs.

Widely adaptable, supporting high power and continuous operation

Features/Advantages: Designed specifically for the high gas volume and continuous operation of laser cutting, capable of supporting the stable gas supply requirements of high-power (e.g., 10,000 watts and above) laser cutting machines. Robust cooling system, capable of handling long-term, high-intensity production tasks.

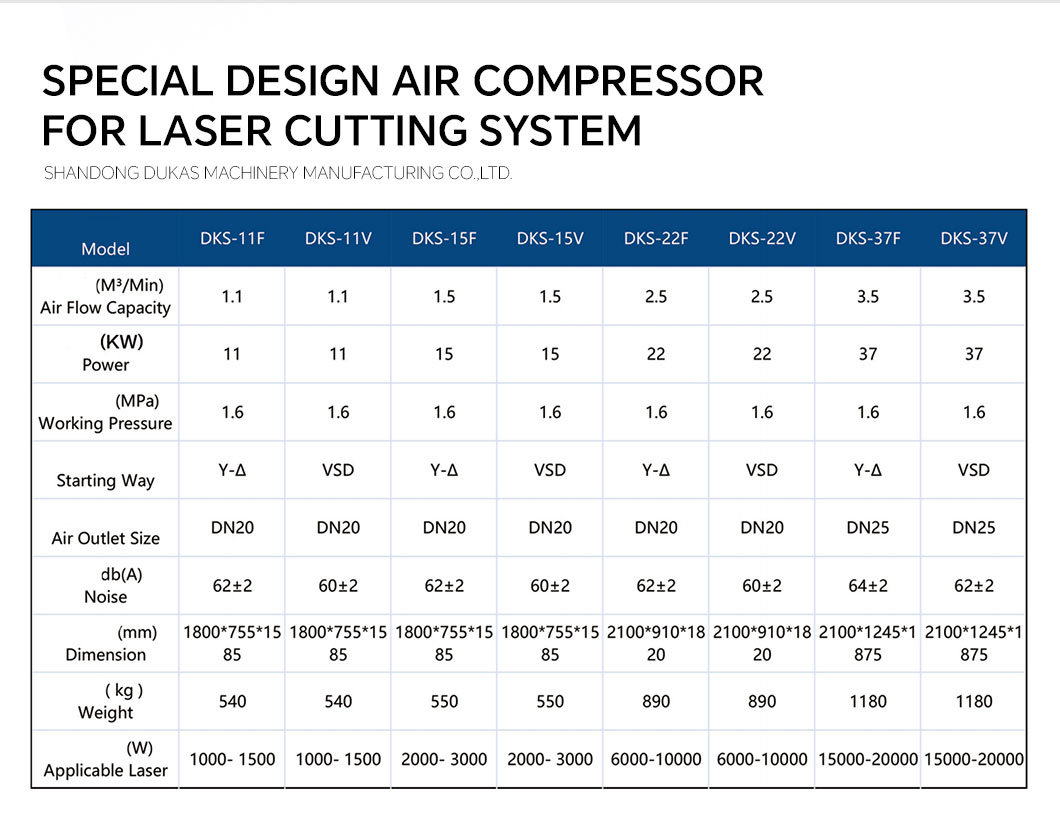

Products categories

-

E-mail

E-mail

-

Phone&

Whatsapp -

Top